Self-healing of concrete

It's the world's most popular building material, and ever since the Romans built the pantheon from it some 2,000 years ago, we've been trying to find ways to make concrete more durable.

No matter how carefully it is mixed or reinforced, all concrete eventually cracks, and under some conditions, those cracks can lead to collapse.

"The problem with cracks in concrete is leakage," explains professor Henk Jonkers, of Delft University of Technology, in the Netherlands.

"If you have cracks, water comes through -- in your basements, in a parking garage. Secondly, if this water gets to the steel reinforcements -- in concrete we have all these steel rebars -- if they corrode, the structure collapses."

Different healing mechanisms :

Autogenous Healing:

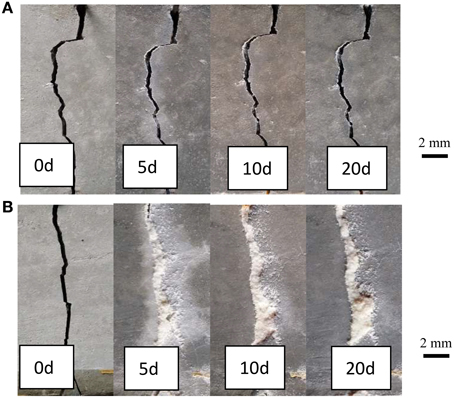

Concrete has an autogenous healing capacity as unhydrated cement is present in the matrix. When water contacts the unhydrated cement, further hydration occurs. Furthermore, dissolved CO2 reacts with Ca2+ to form CaCO3 crystals. These two mechanisms, however, may only heal small cracks. To enhance the healing mechanism, microfibres are added to the mixture. By mixing microfibres in the concrete, multiple cracking occurs. So, not one wide crack, but several small cracks are formed, which close more easily due to autogenous healing.

Superabsorbent polymers (SAP), or hydrogels:

Superabsorbent polymers (SAP), or hydrogels, are able to take up a large amount of fluid (up to 500 times their own weight) and to retain it in their structure without dissolving. When cracks occur, SAP are exposed to the humid environment and swell. This swelling reaction partly seals the crack from intruding potentially harmful substances. After swelling, SAP particles desorb and provide the fluid to the surrounding matrix for internal curing, further hydration and the precipitation of CaCO3. In this way, cracks may close completely.

Due to the fact that the pH in concrete drops from 12.8 to 9-10 when a crack occurs, it is useful to do research in pH sensitive hydrogels. Their swelling capacity can be controlled with the pH. These will only swell when a crack occurs.

calcium carbonate precipitating micro-organisms :

Cracks can be healed by using calcium carbonate precipitating micro-organisms. These organisms are embedded in the concrete matrix after immobilization on diatomaceous earth, and will start the precipitation of CaCO3 once a crack occurs. Through this process the bacterial cell will be coated with a layer of calcium carbonate, resulting in death of the micro-organism, but in the meantime the crack faces may be bond together

encapsulated polymers:

One of the research programs considers the use of encapsulated polymers in order to obtain self-healing of concrete cracks. When a crack appears, the capsules break and the content is released. Due to capillary action, the agent will flow into the crack. After reaction, the crack faces are bonded together and the crack is thus healed.

Depending on the required regain in properties, different healing agents have been encapsulated. In order to reduce the water permeability of cracked concrete, polyurethane is provided inside the capsules. When strength regain is a more important issue, methyl methacrylate is encapsulated. For structures where the aesthetic aspect is important, water repellent agents can be encapsulated.

Depending on the required regain in properties, different healing agents have been encapsulated. In order to reduce the water permeability of cracked concrete, polyurethane is provided inside the capsules. When strength regain is a more important issue, methyl methacrylate is encapsulated. For structures where the aesthetic aspect is important, water repellent agents can be encapsulated.

As encapsulation material brittle glass or ceramic tubes were always used up to now. However, as these will not be able to survive the mixing process in concrete, research is currently focusing on the development of capsules with suitable properties to survive the mixing process and to release the healing agent when cracks appear in the hardened matrix.

While fly-ash and blast-furnace slag concrete:

While fly-ash and blast-furnace slag concrete seem to be inferior with regard to the early age microstructure and strength development, their self-healing capability can be much higher, precisely because of the low hydration degree of the slag and fly-ash particles. Upon cracking, the unreacted particles can be activated again in order to close the crack and to regain water impermeability and strength. The suitability of different types of alkali-activators (e.g. NaOH, KOH or silicate solution) is investigated.

Advantages:

- Decreased production of concrete.

- Lower maintenance & repair cost.

- Curbed carbon dioxide emission from concrete production.

- applicable to existing buildings in form of spray.

Disadvantages:

- The first issue is that the clay pellets holding the self-healing agent comprise 20% of the volume of the concrete. That 20% would normally comprise harder aggregate such as gravel. The clay is much weaker than normal aggregate and this weakens the concrete by 25% and significantly reduces its compressive strength.

- The second disadvantage is the cost of self-healing concrete is about double that ofconventional concrete

DISCLAIMER:

ALL ABOVE INFORMATION ARE COLLECTED AND GATHERED TOGETHER FROM DIFFERENT SITES.

Self Healing Concrete - Civil Researches, Project And Inventions >>>>> Download Now

ReplyDelete>>>>> Download Full

Self Healing Concrete - Civil Researches, Project And Inventions >>>>> Download LINK

>>>>> Download Now

Self Healing Concrete - Civil Researches, Project And Inventions >>>>> Download Full

>>>>> Download LINK